Honing

The honing process provides the final sizing and creates the desired finish pattern on the interior of tubing or cylinder bores. Finishing is accomplished by expanding abrasive stones of suitable grit and grade against the work surface. The stones are rotated and reciprocated in the part with hone abrasive under controlled pressure. Combining rotation and reciprocation produces a cross-hatch pattern in the surface of the part being honed.

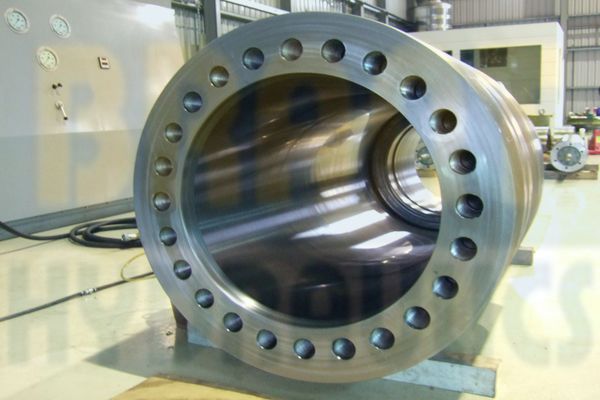

Brant Hydraulics Honing Center is the birth and development of Hydraulic Cylinders, its performance and working condition directly affect the quality, grade, service life and the working environment of the hydraulic service products. From the perspective of this process, honing is the most important precision manufacturing technology of cylinder work surface.

Honing process characteristics

(1) honing is an efficient way of machining the surface of work-piece to achieve high precision, high surface quality and high life span. It can effectively improve the precision of dimension, shape precision and decrease of Ra value, but can not improve the accuracy of hole and other surface.

(2) it can process cast iron parts, hardened and unhardened steel parts and bronze pieces, but it is not suitable for non-ferrous metal parts with large toughness.,

(3) honing is mainly used for hole processing. In the process of hole honing, it is guided by the former machining hole center. The range of machining aperture is phi 5 ~ phi 500 and the depth ratio can be 10.

(4) honing is widely used in bulk production of cylinder holes, oil cylinders, valve holes, and many kinds of guns. It can also be used in small batch production.

(5) when honing, the coaxial degree cannot be determined.

(6) compared with grinding and grinding, honing has the characteristics of reducing manual labor, high productivity, and easy to realize automation.

Contact us or Email us for more details.