Hard Chrome Plating

Hard Chrome Plating is an electrolytic method of depositing Chrome for engineering applications, from a Chromic acid solution.

Deposits can be applied from .25 – 1,000 microns thickness for a wide range of applications, from common engineering alloys, with high levels of adhesion to the substrate. The thinner deposits being used to substantially increase the life of components in wear applications or corrosive environments, and the thicker deposits being used for salvage and repair of worn, damaged or mis-machined components. The plating is extremely hard at around 1000Hv and combined with a high level of toughness, which distinguishes hard chrome from other hard facing coatings. Hard Chrome enhances durability, wear and hardness whilst creating a low co-efficient of friction therefore making it ideal for metal to metal sliding applications.

Hard Chrome Plating is classed as a “COLD” process, the operating temperature of 50 – 60°C ensures no detrimental effects to the physical or mechanical properties of the base materials. Hard Chrome can be deposited successfully and advantageously onto most metallic substrate materials..

Brant Hydraulics can offer four variants; standard hard chrome plating, thin dense chrome, precision hard chrome and flash chrome dependant on the application.

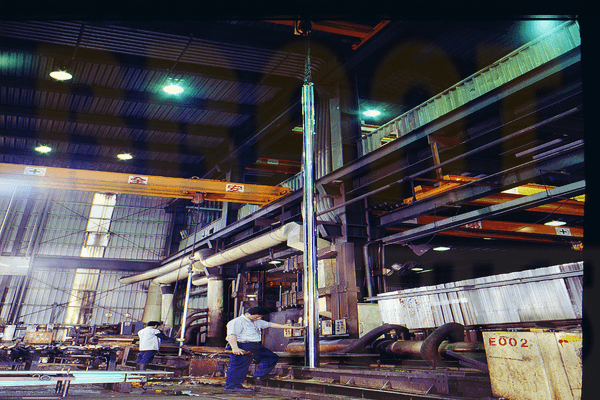

Hydraulic cylinders in the general mechanical engineering field, as well as in extreme operating environments. Brant Hydraulics offers highly specialized rod coatings options to meet the need for every environment and budget of our customers.

Contact us or Email us for more details.