How do Hydraulic Cylinders Work?

Brant Hydraulics will take you through the basics of a Hydraulic Cylinder.

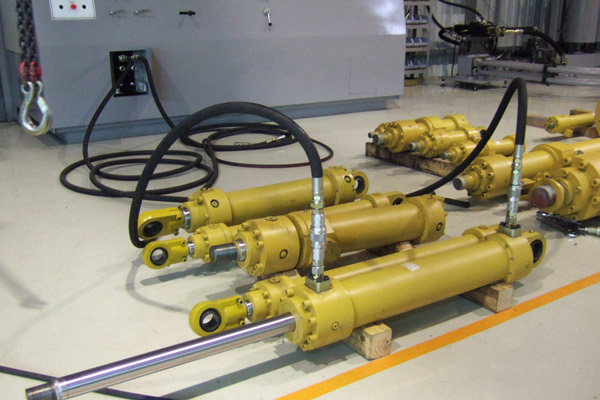

The history and fundamentals of Hydraulic cylinders haven’t really changed a lot over the years. Hydraulic cylinders and the concept of hydraulics are everywhere in our daily life. The whole manufacturing processes are much more streamlined and the tolerances are much tighter, but for the most part cylinders are still the hard working push/pull tools they have always been. These things have literally shaped the world around us. Anything that gets lifted, pushed, hauled, dumped, dug, crushed, drilled or graded has gotten that way by some truck, crane, dozer or tractor using a hydraulic cylinder. We will find out, HOW DO HYDRUALIC CYLINDERS ACTUALLY WORK !!!

The amazing amount of force a cylinder exerts is due to the simple mechanical principle of pressure exerted on the surface area of the piston. Simply put, the larger the diameter of the cylinder, the more it will lift. The formula for this is Area X PSI (Pounds per square inch) = Force.

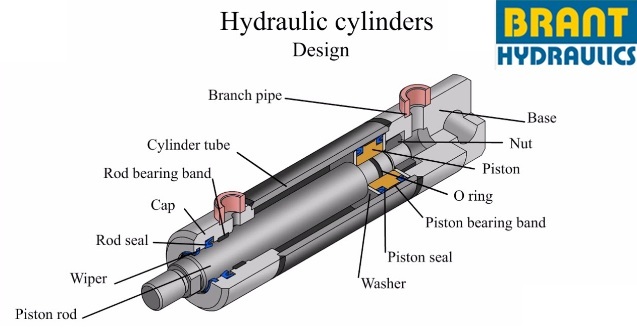

A Hydraulic cylinder consists of numerous delicate parts and components. All of them are linked with one another. Every part or component plays a crucial role in making the hydraulic cylinder to function properly.

The PISTON is inside the cylinder, the diameter of which is known as the BORE. OK, Technically, the bore is the inside diameter of the tubing but this difference is of minor significance. The piston needs a piston seal to keep the pressure from bypassing to the other side, which allows it to build the required pressure (If a cylinder isn’t lifting the force it should, the piston seal is probably worn).

The piston is attached to the ROD (or shaft) of the cylinder, usually with the rod passing through the piston and attached with a large nut on the opposite end. To correctly calculate the pulling force of a cylinder, the surface area of the rod must be subtracted from the formula. The rod is probably the hardest worked component in the whole system. The rod is the largest single chunk of steel in the cylinder, unpainted and exposed to all the elements. It has to be extremely strong (to resist bending), exceptionally hard (to resist corrosion and pitting), and smooth as silk (to keep the rod seals intact to prevent leakage of fluid and pressure). The STROKE of the cylinder is the total travel possible from the fully retracted length and the fully extended length of the rod.

The GLAND or “head” of the cylinder is the part that the cylinder rod extends and retracts through. It contains the rod seals & the wiper seal which keeps contamination out of the cylinder.

The BUTT is the base or “cap” end. This end usually can use a variety of attachment points. Speaking of attachments, how do cylinders attach to their implement? Usually by using a CLEVIS, CROSS TUBE, PIN-EYE or TANG.

The Seals and O-rings, these small and not eye-catching rubber made materials, play a crucial part for hydraulic cylinders while they are in motion. Many seals / o-rings are used in a hydraulic cylinder, they are meant to prevent any hydraulic fluid leaking, some can even resist high heat, depend on their materials.

Most commercially available cylinders are double-acting which means they have ports on each end and they are used to push AND pull. These are easy to convert to single-acting (push or pull only) by using a simple breather device to allow the air on the unused side to be expelled.

So that’s pretty much all there is to hydraulic cylinders and how they work! They really are simple devices, capable of doing tremendous amounts of work. We will talk about others as we move on.

If you have any questions or inquiries, please don't hesitate to contact us to let us know your opinions. We have a team of experienced engineers to work with you. Thank you.