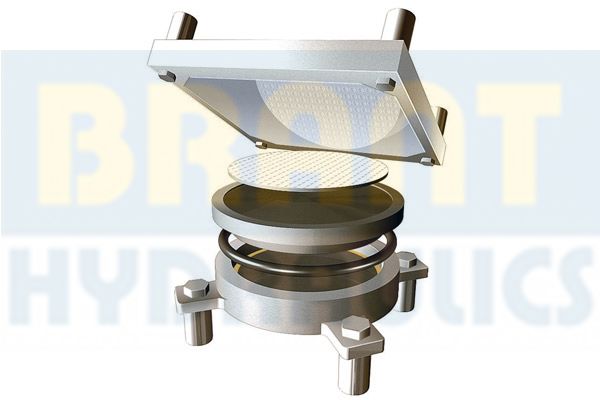

Pot Bearing (Round Base)

Pot Bearing with Large Load Capacity and Large Horizontal Displacement

Pot bearing is a kind of new type bearing which is composed of pot, elastomeric pad, stainless steel plate, sealing ring and other components. It is designed for bearing the combinations of vertical loads, horizontal loads, longitudinal and transverse displacements and rotations. Pot bearing is ideal bearing for large bridge with the features of large horizontal displacement, light weight, simple structure and easy operation.

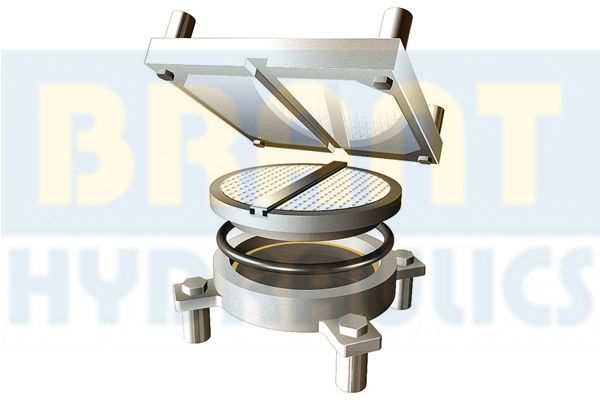

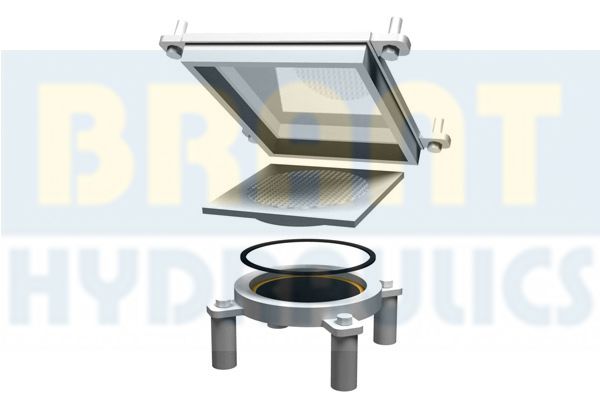

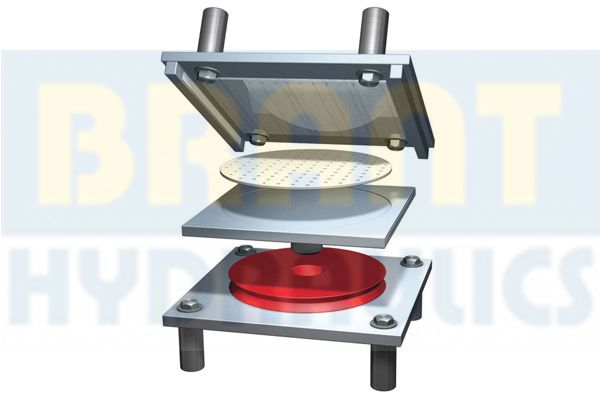

The main components of pot bearing.

Working Principle

There is an elastomeric pad in the pot of the pot bearing, it has fluid properties when it in the state of three-phase stressed, making use of this feature can achieve large rotation of the bearing. In addition, when a relative motion occurs between the PTFE plate which placed on the piston and the stainless steel plate, horizontal displacement can be achieved. Pot bearing can meet the requirements of large end reaction, large horizontal displacement and large rotation, it is suitable for the bridge with large span and large end reaction.

Categories

In addition, according to the displacement ability, pot bearing can be divided into three types: fixed pot bearing (GD), guided sliding pot bearing (DX) and free sliding pot bearing (SX). Fixed pot bearing and guided sliding pot bearing can also be divided into common pot bearing and damping pot bearing. The appearance of these pot bearings is similar, but the difference of internal structure directly determines whether the bridge can be displaced.

Fixed Pot Bearing – Rotation Performance Only

Fixed pot bearing consists of top and bottom steel plates, stainless steel plate, piston, brass sealing ring and elastomeric pad. The internal sealing ring enables the piston to rotate under load. This kind of pot bearing has rotation performance but restricts all displacement in planar axis.

Guided Sliding Pot Bearing – Rotation performance & one-direction sliding

Guided sliding pot bearing is identical in construction to free sliding pot bearing, but two guides are fixed at the top steel plate for bearing pad movement limitation. It has vertical rotation performance and one-way sliding performance. And there are two kinds of types about this protect: edge guided sliding pot bearing and center guided sliding pot bearing.

Free Sliding Pot Bearing – Rotation performance & multi-direction sliding

Free sliding pot bearing has the same structure with the fixed pot bearing, besides there also a PTFE plate above the piston to enable the bearing to slid in all directions. It has vertical rotation, vertical and horizontal sliding performances.

Feature

- Providing longer service life compared to elastomeric bearing pad.

- Large horizontal displacement and large bearing capacity.

- Accommodate rotations at any axis and the appropriate movements of the bridge.

- Totally detachable, and easy to dismantle if any element has to be replaced.

- Saving steel and reduce costs.

Specification

- Material: steel, elastomer.

- Shape: round and rectangular.

- Hardness (shore A): 55–65.

- Capacity: 1000–70000 kN.

- Displacement: 0–300 mm.

- Normal temperature type bearing: suitable for -25 °C to 60 °C.

- Cold resistant type bearing: suitable for -40 °C to 60 °C.

- Certification: CCC, SGS, CE, ISO.

- Package: plastic, wooden or tin box.

Application

Pot bearing is mainly used in such fields

- Bridge which the structure with rotations in various directions.

- Large curved or skewed bridge.

- Highway.

- Other fields which also need to meet the need of large load and rotation.

We do have many other types of dampers products available.

Please Contact us or Email us for more details.