High Damping Rubber Bearing

High Damping Rubber Bearing – Fixed and Sliding Types for Large Displacement

High damping rubber bearing, also called HDR bearing pad, is one of seismic isolation bearing. It has excellent seismic isolation performance to effectively reduce the bridge damage caused by earthquake.

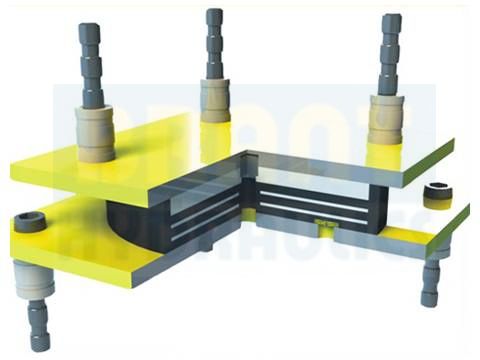

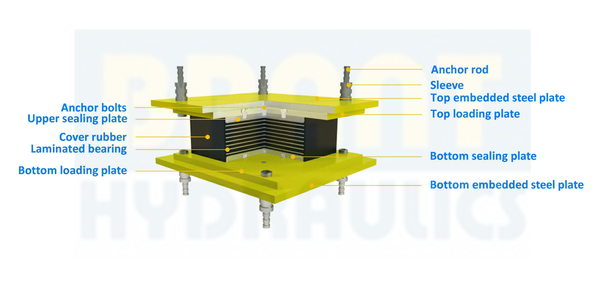

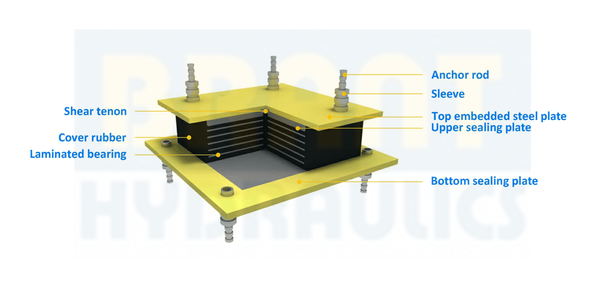

HDR bearing pad is composed of specialized designed rubber with high damping performance, sandwiched together with steel plate layer. When installing, the high damping rubber bearing is commonly used with top and bottom steel plate and connection accessories.

Working principle

During earthquake, the vibration from various directions will impact fixed base building and results in deformation and building or bridge damages. The high damping bearing pad is improved through high damping material, which the damping ratio can approach to 15% to 18%.

When the earthquake comes, the high damping rubber bearing will increase the horizontal displacement through rubber shear deformation and reduce friction coefficient. The large displacement can weaken the vibration from all direction and reduce the damage of building and bridges.

Joint structure

- The HDR (Ⅰ) rubber bearing. It is designed with top and bottom embedded steel plate. And the rubber bearing is connected with pier and beam by sleeve. The top and bottom loading plate is connected with sleeve by anchor bolt. The top and bottom embedded steel plate is connected with sleeve by welding.

- HDR (Ⅱ) rubber bearing. It is designed with top embedded steel plate and without bottom embedded steel plate. The bottom loading bearing is connected with sleeves with anchor bolts. The top embedded steel plate is connected with top loading plate with shear tenon. And the top embedded steel plate is connected with sleeve by welding.

Damping structure

-

Fixed type (HDR rubber bearing). The high damping rubber has excellent horizontal shear performance to bear the horizontal force. It can absorb vibration through large displacement in horizontal direction and hysteretic energy.

- Rectangular HDR rubber bearing.

- Round HDR rubber bearing.

-

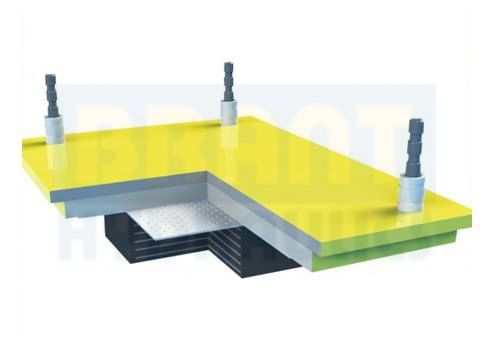

Sliding type (LNR rubber bearing). The displacement is achieved by sliding friction. The top stainless steel plate and PTFE sliding plate can reduce friction coefficient and achieve large displacement for shock absorption.

- Rectangular LNR rubber bearing.

- Round LNR rubber bearing.

Production & Package

We have advanced equipment for producing high damping rubber bearing.

- The high damping rubbers and steel plates will be vulcanized in professional equipment.

- Then the laminated bearing pads will be connected with top and bottom steel plate through anchor bolts.

- Then the steel plate will be painted into different colors. The popular color is orange, blue and yellow. Other colors can be customized.

- High damping bearing rubber will be packed with plastic films to protect bearing rubbers from moisture, dust and impact.

Technical Parameters

Specifications

- Working temperature range: -40 °C to +60 °C.

- Rad: 0.006 rad and 0.008 rad.

-

Damping ratio:

- HDR (Ⅰ) bearing rubber: 15%.

- HDR (Ⅱ) bearing rubber: 12%.

- LNR bearing rubber: 10%.

-

Technical parameters

- HDR (Ⅰ) bearing rubber – Rectangular Fixed

- HDR (Ⅰ) bearing rubber – Round Fixed

- HDR (Ⅱ) bearing rubber – Rectangular Fixed

- HDR (Ⅱ) bearing rubber – Round Fixed

- LNR Rubber Bearing – Rectangular Sliding

- LNR Rubber Bearing – Round Sliding

Feature

- Excellent horizontal displacement. absorb shock energy effecively.

- Excellent reset structure. there is no residual displacement.

- High damping material. 10% to 18% damping capacity for shock absorption.

- Wide range structure for different environments and displacement requirements.

- Economical and high performance for lower total construction budget.

- Easy installation and replacement for lower maintenance cost.

Application

High damping rubber bearing is widely used in the quake-prone areas for bridge, building and other constructions.

We do have many other types of dampers products available.

Please Contact us or Email us for more details.